Business Requirement: Transfer material from Seattle Organization to Boston Organization.

There are two ways to transfer material from one organization / warehouse to other organization.

1. We can transfer material across inventory organization through Internal Requisition / Internal Sales Orders

2. Inter-Organization Transfer from Inventory Application.

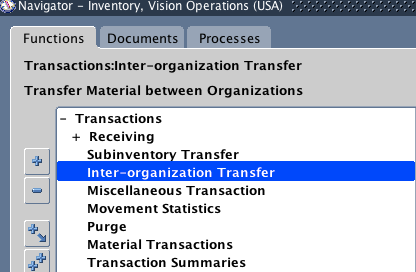

Navigation: Inventory Responsibility > Transactions > Inter – Organization Transfer

Select M1 organization from the Org List if you already haven’t selected.

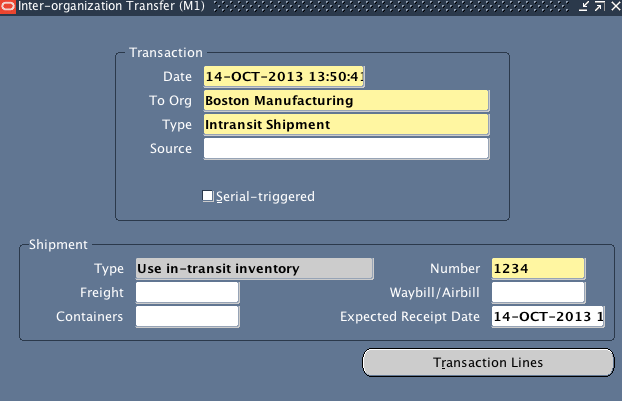

Enter the Organization to which you would like to transfer the material. In this case we would like to transfer material to Boston warehouse.

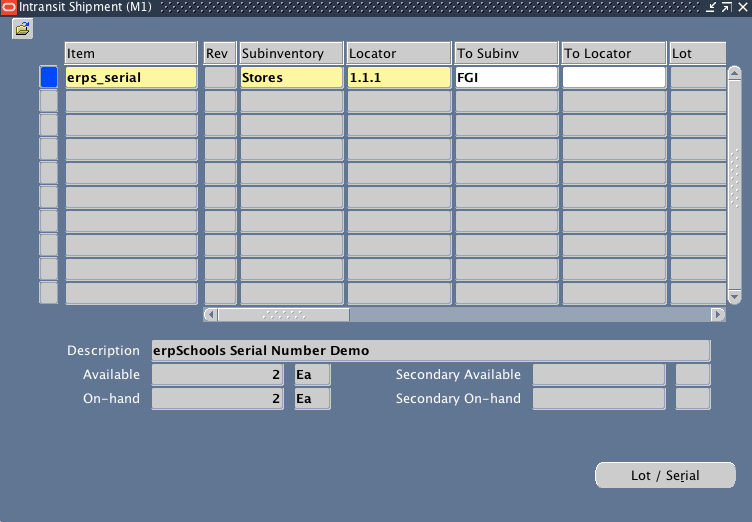

Click Transaction Lines button and enter item information.

Choose sub inventory , Locator or both source organization and destination organization.

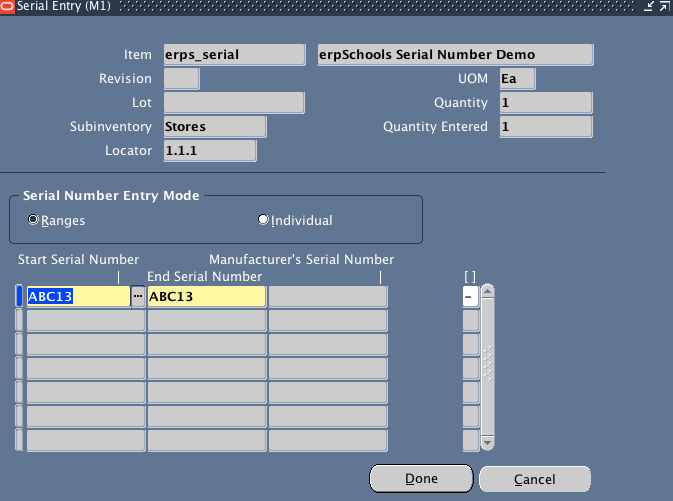

If the item is either Lot controlled or Serial Controlled enter the necessary information.

Click Done and Save the transaction.

Now the Transaction is initiated in Seattle organization, Next step is to receive the material in Boston Organization.

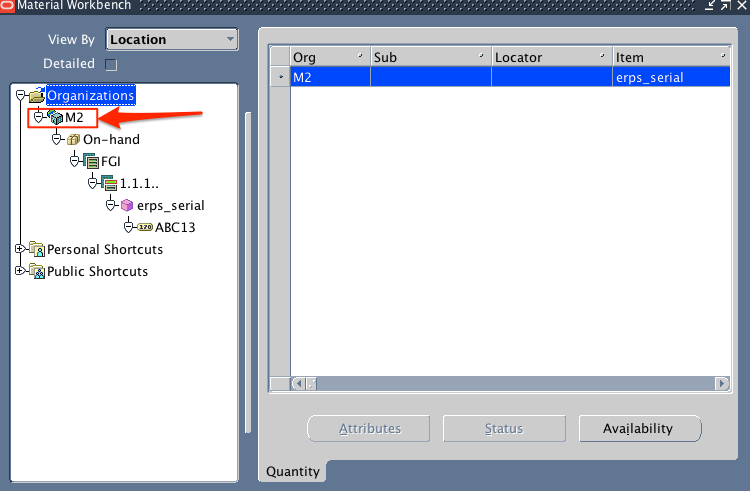

Navigation: Inventory Responsibility > change Organization

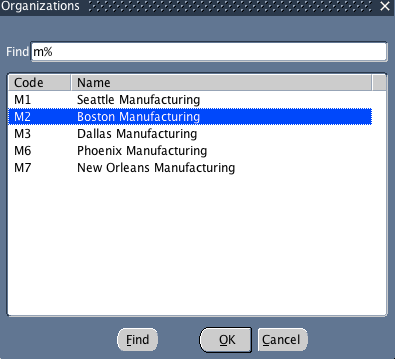

Select M2, Boston Manufacturing Organization before processing to creating Inventory Receipt.

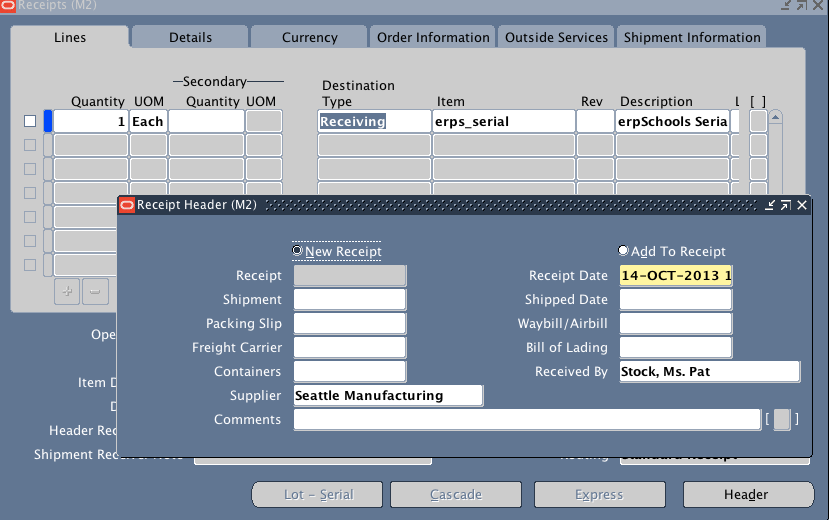

Create Inventory Receipt in Boston Organization

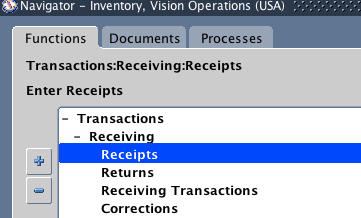

Navigation: Receiving >Receipts

Query based on item number or Order number

Enter the serial number which is received and Save the transaction.

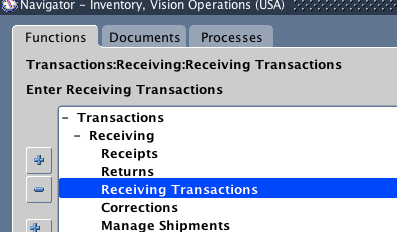

Once Inventory Receipt is created and material is received into Receiving area we need to move this material into warehouse by creating “Receiving Transactions”.

Creation of “Receiving Transaction” is not required all the time, it depends on what type of “Receipt Routing” you are following for the selected item. If the Receipt Routing is standard then we need to create Receiving Transaction. If the Receipt Routing is “Direct” then we don’t need to perform the next step.

Navigation: Inventory Responsibility > Transactions > Receiving > Receiving Transactions

Query the item number , enter information as needed and Save the transaction.

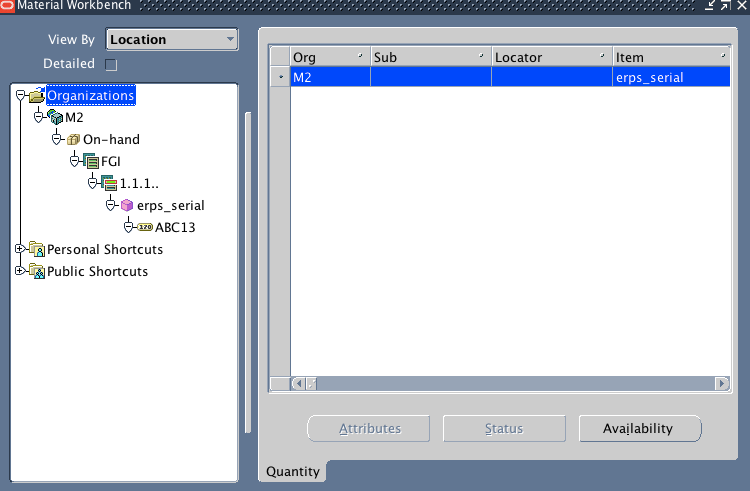

Now check the on-hand quantity screen in M2 Organization to ensure material is moved properly.